Self-locking nuts

The Self Lock Nuts

A security principle made of 100% stainless steel, without any use of nylon or plastic.

Nuts with their internal thread form the counterpart of a screw and ensure that the attached screw does not come loose. Under heavy loads of the screw connections, it may sometimes loosen on its own which ultimately leads to a failure of the connection. This is easily caused by external influences such as weather or corrosion. However, proper bolt locking should hold a bolted connection even under dynamic loading and heavy vibration or impact.

The special shape of the thread of the Self Lock Nuts effectively prevents failure and at the same time reuses the nut. The number of components is also reduced by the self-locking feature of the nut, since no further securing elements are needed. The screw lock counteracts the unintentional release, without the need to process the screw itself.

Function of the thread lock

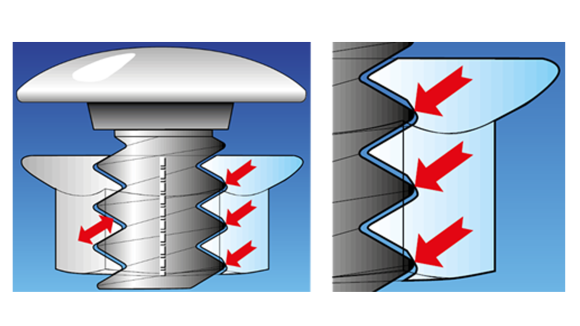

The Self Lock Nuts are made with a specific tap that cuts a self-locking thread on the nut. Thus, the thread lock is already "installed" in the internal thread. This modified thread profile consists of wedge surfaces which point in the loading direction. These wedge surfaces have a pitch angle of 30 ° and thus lead to a self-locking.

Securing

The pictures show the thread geometry. Here, the wedge surfaces are clearly visible on the right side of the thread. This angle, which acts selectively on the thread of the screw, creates the inhibiting effect and thus the securing of the Self Lock Nut.

The self-locking hexagon nuts with clamping part can be used in particular in the following industries:

- rail and traffic

- energy

- construction and forestry machines

- shipbuilding industry

- error-free and easy installation

- possible use of standard external threads (screws) with "medium" tolerance class

- uniform distribution of tension forces on all threads

- No tearing of the threads

- affordable, as no additional parts are needed

- reuse without degradation

Further advantages without undercutting:

- no damage to the surface on the workpiece/counter material

- corrosion resistance is thus not affected

Our product and system solutions

Together with you we will develop the best possible logistics solution according to your needs and structure:

- centrally in the material warehouse

- centrally at a defined location in production

- decentralised in every area of production with the articles needed there

With us, you will always find the right product.

Every single industry requires products that are geared to very specific purposes. To support the requirements of a market holistically, we consistently analyse the current needs and future requirements of our customers.

This resulted in our W.TEC® product series with products for requirements-based solutions and industry-specific innovations. We guarantee optimal and consistent quality and first-class technical service. We can give you expert advice and best practices so that you will always find the right product, be it plastic cabs, slings, screws for thermoplastic materials or many more.

Contact

We are here for you!

Please contact us by telephone +46 10 121 99 00 or

via email to order@wuerthindustri.se.

The Würth Industrie Service GmbH & Co. KG collects and processes the personal data provided in the form in order to process the requested request for you. Please note the mandatory fields in the forms. The legal basis for this processing, the absolutely necessary data, is Art. 6 para. 1 lit. b DSGVO, implementation of a pre-contractual measure. The processing of data voluntarily provided by you is carried out on the basis of Art. 6 para. 1 lit. f DSGVO. Thereafter, processing is permissible which is necessary to safeguard our legitimate interests. Our legitimate interest is to have contact with you, our customers, to improve our consulting quality and to be able to contact you more easily in case of possible queries. The data collected will only be stored by us for as long as is necessary to process your enquiry and to contact you. They are then deleted.

Supplementary data protection information, in particular regarding your rights to information, correction, deletion, restriction of processing, objection and complaint, can be found in our data protection declaration.